Mashiinka kala soocida midabka & digirta midabka

Hordhac

Waxaa loo isticmaali jiray bariiska iyo baastada, digirta iyo digirta, sarreenka, galleyda, sisinta iyo digirta kafeega iyo kuwa kale.

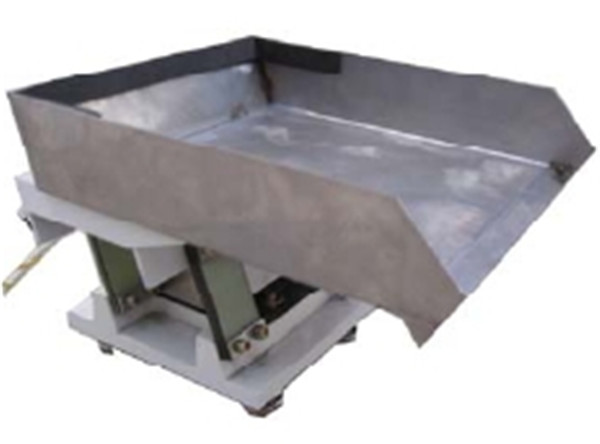

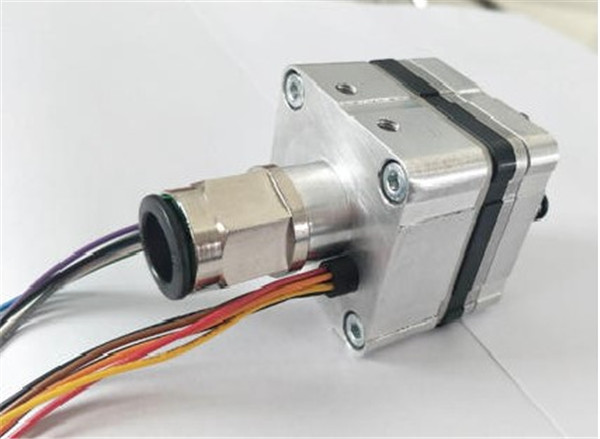

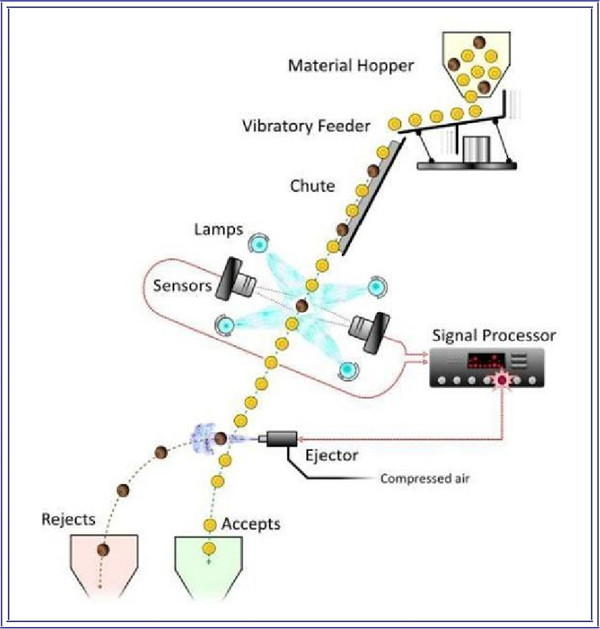

Qalabka quudinta gariir-gariir

Habka gariirada quudinta, walxaha la doortay waa la gariirayaa waxaana loo gudbiyaa marinka wadada hopper. Nidaamka xakamaynta ayaa xakameynaya qadarka weyn ee gariiriyaha iyada oo loo marayo hagaajinta ballaca garaaca wadnaha Yaryar, si loo gaaro hagaajinta socodka mashiinka oo dhan

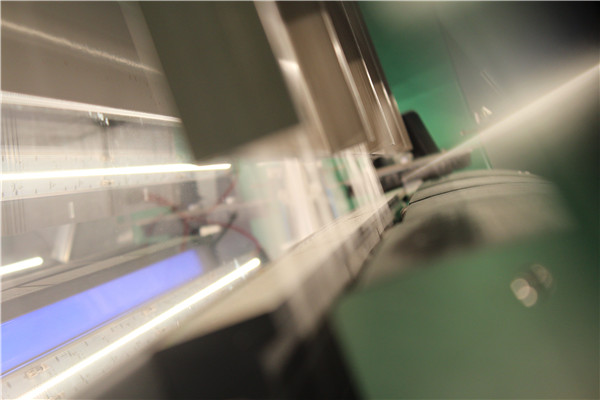

Soo dejinta qalab-channel-ka

Wadiiqada meesha ay alaabtu hoos u soo dedejiso si loo hubiyo in walxaha soo galaya qolka kala-soocidda la kala saaro Dharka ayaa la mid ah oo xawaaruhu waa mid joogto ah, si loo hubiyo saameynta xulashada midabka.

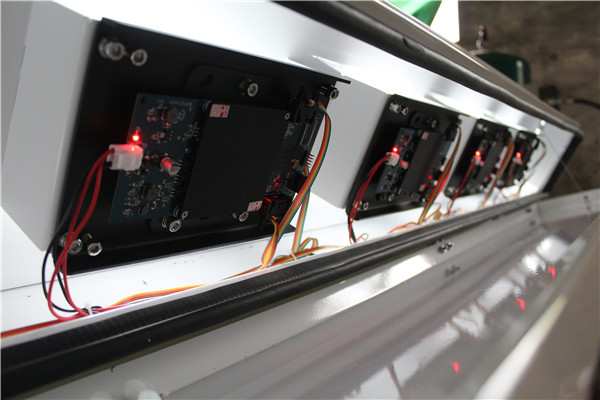

Qolka kala-soocidda nidaamka indhaha

Qalabka ururinta iyo kala-soocidda, isha iftiinka, qalabka hagaajinta asalka, CCD

Waxay ka kooban tahay aaladda kamarada, fiirsashada iyo muunada daaqada, iyo qalabka ka saarida boodhka.

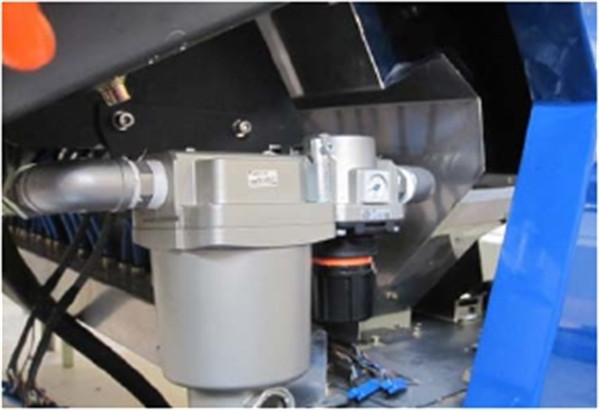

Waalka buufinta hab-dhiska

Marka nidaamku u aqoonsado shay gaar ah inuu yahay badeecad cilladaysan, tuubada buufinta waxay soo saartaa gaaska si loo baabi'iyo walxaha. Sawirka hoose wuxuu muujinayaa nozzles-yada si fudud loogu arki karo mashiinka.

Qalabka xakamaynta-sanduuqa kantaroolka korantada

Waaxdan Nidaamku wuxuu mas'uul ka yahay ururinta, xoojinta, iyo socodsiinta calaamadaha sawir-qaadista, iyo soo dirida amarrada lagu kaxeynayo valve buufin iyada oo loo marayo qaybta koontaroolka si loo buufiyo cadaadiska hawada ayaa soo saarta diidmada, dhamaystirta shaqada xulashada midabka, oo ay gaarto ujeedada xulashada.

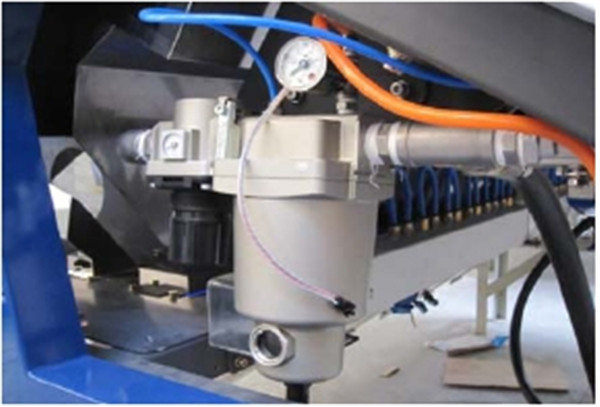

Nidaamka gaaska

Waxay ku taallaa dhinaca bidix iyo midig ee mishiinka, waxay bixisaa nadaafad sare oo hawo cadaadis leh mashiinka oo dhan.

Dhismaha Mashiinka oo dhan

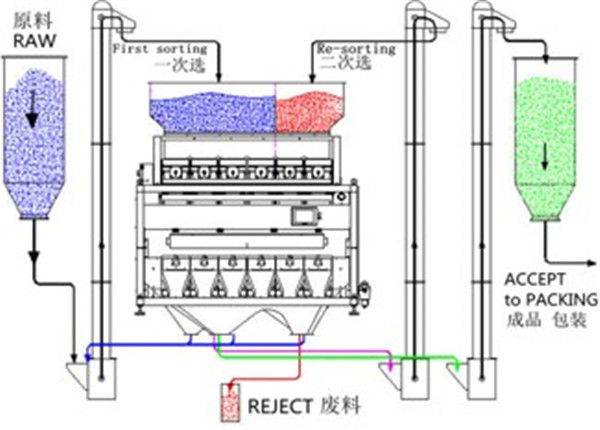

Ka dib markii alaabtu ay ka soo galaan kala-soocida midabka sare, kala-soocidda midabka ugu horreeya ayaa la sameeyaa. Qalabka u qalma waa alaabta la dhammeeyey. Qalabka diidmada ah ee la doortay waxaa loo diraa kanaalka xulashada midabka sare ee isticmaalaha iyada oo loo marayo qalabka kor u qaadida ee xulashada midabka sare. Qalabka iyo walxaha u qalma ee kala-soocidda midabka sare waxay si toos ah u galaan alaabta ceeriin ama ku soo celi tan ugu horeysa iyada oo loo marayo qalabka kor u qaadista ee uu diyaariyay isticmaaluhu. Kala-soocidda labaad waxaa loo fuliyaa midab-kala-soocidda labaad, iyo walxaha la diiday ee kala-soocidda midabka labaad waa alaabta qashinka ah. Habka midabaynta saddexaad waa la mid

Kala soocida midabka wada sheekaysiga socodka shaqada

Nidaamka oo dhan

Faahfaahinta ayaa muujinaysa

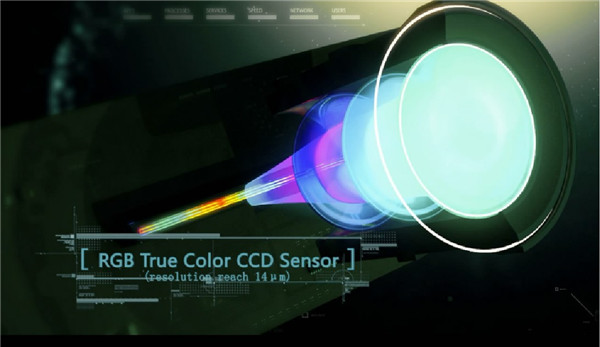

midabka dhabta ah ee CCD sawirka nidaamka qabsashada

Valve Solenoid Tayada Sare leh

CPU-ga ugu Wanaagsan Nidaamka oo dhan

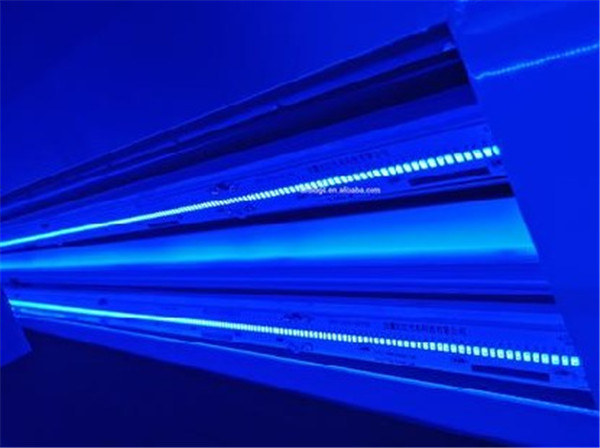

Iftiinka LED

Tilmaamaha farsamada

| Qaabka | Soosaarayaasha (kombiyuutarada) | Chutes (kumbuyuutar) | Awood (Kw) | Voltage(V) | Cadaadiska Hawada (Mpa) | Isticmaalka Hawada (m³/min) | Miisaanka (Kg) | Cabirka (L*W*H,mm) |

| C1 | 64 | 1 | 0.8 | AC220V/50Hz | 0.6 ~ 0.8 | 1 | 240 | 975*1550*1400 |

| C2 | 128 | 2 | 1.1 | AC220V/50Hz | 0.6 ~ 0.8 | 1.8 | 500 | 1240*1705*1828 |

| C3 | 192 | 3 | 1.4 | AC220V/50Hz | 0.6 ~ 0.8 | 2.5 | 800 | 1555*1707*1828 |

| C4 | 256 | 4 | 1.8 | AC220V/50Hz | 0.6 ~ 0.8 | 3.0 | 1000 | 1869*1707*1828 |

| C5 | 320 | 5 | 2.2 | AC220V/50Hz | 0.6 ~ 0.8 | 3.5 | 1 100 | 2184*1707*1828 |

| C6 | 384 | 6 | 2.8 | AC220V/50Hz | 0.6 ~ 0.8 | 4.0 | 1350 | 2500*1707*1828 |

| C7 | 448 | 7 | 3.2 | AC220V/50Hz | 0.6 ~ 0.8 | 5.0 | 1350 | 2814*1707*1828 |

| C8 | 512 | 8 | 3.7 | AC220V/50Hz | 0.6 ~ 0.8 | 6.0 | 1500 | 3129*1707*1828 |

| C9 | 640 | 10 | 4.2 | AC220V/50Hz | 0.6 ~ 0.8 | 7.0 | 1750kii | 3759*1710*1828 |

| C10 | 768 | 12 | 4.8 | AC220V/50Hz | 0.6 ~ 0.8 | 8.0 | 1900kii | 4389*1710*1828 |

Su'aalaha macaamiisha

Waa maxay sababta aan ugu baahanahay mashiinka kala soocida midabka?

Hadda oo sharuudaha nadaafaddu ay sare u kacayaan, midabyo badan oo kala soocida ayaa lagu dabaqayaa warshadda sisinta iyo digirta, gaar ahaan warshadda kafeega iyo warshadaynta bariiska. Kala-soocida midabka ayaa si wax ku ool ah uga saari karta walxaha midabka kala duwan ee digirta qaxwaha ugu dambeeya si loo hagaajiyo nadiifnimada.

Ka dib marka lagu farsameeyo kala-soocida midabka, nadiifnimadu waxay gaari kartaa 99.99% . Si ay mirahaaga iyo bariiska iyo digirta qaxwaha uga dhigaan kuwo qiimo badan.